HOMECALENDAR RESULTS LINKS RULES PHOTO ALBUM

BUILD A MINI

Last updated 15 October 2023

Mardave Mini Assassin Build Instructions

General notes

Screws into non-nyloc nuts or other threaded metal parts should be thread-locked

to ensure they do not come loose.

Front Suspension

Assemble as shown in the instructions; ensure that the front hub is the correct

way up, the plastic boss on the hub goes inside the spring. The kingpins now

come with a smooth coating so they don’t need to be polished, but you do need to

ensure that the hub moves freely on the kingpin.

When bolting to the chassis use a total of 4mm of spacers in the front lug, and

2mm of spacer in the rear. This should give you the correct ride height (3.5 to

4mm) with the tyres supplied. Adjusting the front ride height is done by

changing these spacers.

.

Rear Pod

Assemble as shown in the instructions. But note that the screw goes through the

other side, not as shown in the instructions.

When fitting the parts to the chassis, leave the centre rear pin loose until the

pod has been attached and ensure the pod moves freely on the pin, don’t forget

to snap the pod plate onto the ball stud, and only screw the spring retaining

nyloc nuts just on far enough for the thread to be through the nyloc section of

the nut, not 5mm further as in the instructions. This should give the correct

ride height with the tyres supplied in the kit. The rear ride height is set by

adjusting these nuts. Note the two rear bodyposts are not part of the kit.

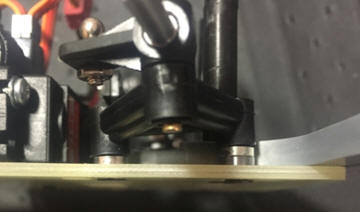

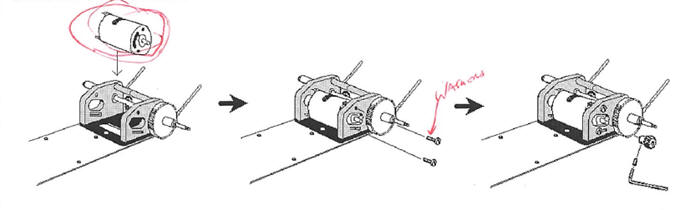

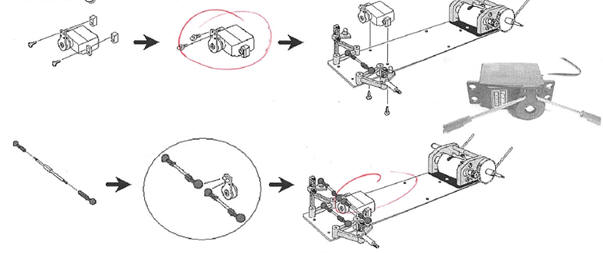

Rear Axle & Motor

Assemble as shown in the instructions. Note that a second gear is used on the

axle, not the spacer shown in the instructions. Solder the wires onto the motor

before fitting it to the pod, but note that the motor goes on the other side of

the pod to that shown in the instructions for normal rotation direction, or fit

it as shown but solder the wires on the opposite way around.

Steering Servo & Tie-Rods

The middle holes on the servo saver are used, and will need to be drilled out

before fitting the black ball studs. The tie-rods have a right hand thread on

one end, and a left hand thread (anti-clockwise thread) on the other. The right

hand thread is indicated by the longer un-threaded portion. The opposite handed

threads allow for toe angle adjustment without removing them from the car. Screw

the ball cups on so roughly the same amount of thread is showing on each end,

and there is approximately 16mm between the ends of the cups. As these are

Schumacher ball grippa cups a Schumacher spanner is helpful when screwing them

on.

Note that the servo in the instructions is shown the wrong way round. It is

important to have the output of the servo on the centre-line of the car. The

best way to achieve this is to use a ruler to put a pencil mark at the centre,

either side of the clearance hole in the chassis and then line up the servo by

eye. Before fitting the saver to the servo, make sure it is centred properly by

connecting all the electrics and powering on.

Bodyposts & bumper

Assemble the rear body post as shown in the instructions. Ensure that the rear

pod still moved freely, you may have to file the back of the posts to ensure

there is clearance.

The front bodyposts hold the bumper onto the chassis. Note which holes to use to

give the best fit of the bumper with the kit Mini bodyshell.

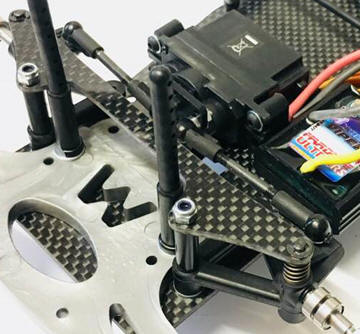

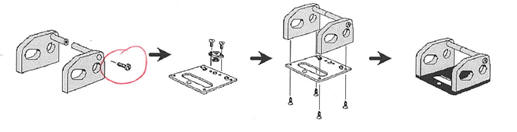

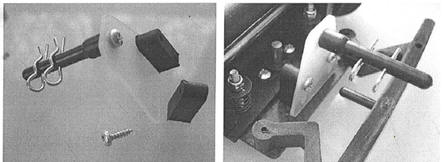

Battery holder

Assemble as shown below. Note which way round the GRP parts are fitted.

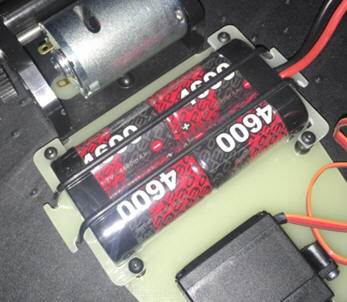

Electrics

Electrics placement is your choice, I would recommend fitting the ESC at the

side of the servo, & the receiver either on the chassis or on top of the servo.

Ensure that they do not foul any moving parts.

Wheels & Tyres

Rear wheels; The nuts should be tightened fully. Ensure that the wheel is fitted

correctly onto the drive from the gear.

Front wheels; one bearing on the inside of the wheel, the other on the outside.

Tighten the nut fully to seat the bearings then slacken it off until the wheel

spins very freely but does not move side to side.

Suspension Settings

Check the ride height front & rear is 3.5mm to 4mm, slightly higher at the rear.

As foam tyres wear, the ride height will need to be checked regularly and

adjustments made to the rear and spacers taken away at the front. Always have

2mm more spacers on the front screw than the rear. Schumacher do a set of

2mm,1mm, &0.5mm spacers, part number U3131.

Set the front toe to have the wheels parallel (zero toe), and the car running

straight.

It is also important to set the rear springs on both sides to avoid tweak. Even

though it’s simple to do, I’m not going to even try to explain the way this is

done using words; it’s something you will need to be shown. Ask one of the

experienced GT12 or LMP drivers to show you how it’s done.

Optional Kingpin brace

This is fitted as shown below. The washers that fit between the spring and the

circlip on kingpins is not required.